Hot Sale Colloidal Silica for Polishing and Coating

| Categories | Colloidal Silica for Polishing |

|---|---|

| Brand | Fusaike Colloidal Silica Manufacturer |

| Classification | Chemical Auxiliary Agent, Hot melt adhesives |

| Other Names: | Silica Sol |

| Usage: | Coating Auxiliary Agents, Paper Chemicals |

| Update Time | Jul 27,2024 |

ITEM | SiO2, % | Na2O, % ≤ | pH value | Viscosity (25),mp a.s ≤ | Density (25),g/cm3 | Average particle diameter,nm |

| JN-30 | 30.0-32.0 | 0.30 | 8.5-10.0 | 7.0 | 1.19-1.21 | 10-14 |

| JN-40 | 40.0-42.0 | 0.3-0.4 | 9.3-9.7 | 25.0 | 1.295-1.30 | 10-20 |

Used as the cohesive agent for various fireproof materials. It has high bounding strengthe and high heat-resisting per-formance(1500-1600C), etc.

♦ Used in coating industry. It makes the paintsfirm. It also possesses features, such as anti-contamination, dustproof, anti-aging, fireproof, ect.

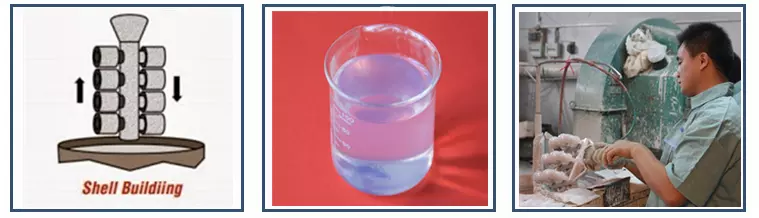

♦ Used in precision casting of thin covers to increase the cover strength, improve the casting smooth finish. Its molding quality is better than that of water glass. It can be used to replace ethy l silicate for molding so as to reduce the costs and help improve the operating conditions.

♦ Having large specific surface area, silica sol can be used for making catalyst and as catalyst carrier.

♦ Used in paper-making industry. It can be used as the anti-glutinous agent of cellophane, pre-treatment agent of photopraphic paper, skidproof agent of cement bags,etc.

♦ Used as sizing agent in textile industry. When used with oil of photographic paper, skidproof agent to processs wool and rabbit hair, it helps improve the processing of wool and rabbit hair, reduce the economic returens.

♦ Used as the treatment agent of silicon steel plates, dispering agent of kinescope and skidproof agent of floor waxes,etc.

♦ Silica content 40% of alkaline silicon sol and can be used for refractory material and polishing processing

♦ Ammonia stable silica sol is mainly used in ceramic fiber and catalyst carrier .

- Tel

- *Title

- *Content